New: Bi-directional CAN Interface – Remote Control via CAN

In many test setups involving power analysis, the majority of the data to be evaluated will come from the power analyzer itself. The automotive environment, however, typically differs a lot. Modern cars can be equipped with hundreds of electronic control units (ECUs) and sensors of different kinds. Within the sea of data points these devices generate, voltage, current and power values are just a minor subset. Nevertheless, this subset needs to be integrated with the remainder of the data for the test engineers to benefit from it.

While ECU and sensor data typically get exchanged over the CAN bus, traditional power analyzers connect via GPIB or Ethernet. Thus, it is up to the test engineers to reconcile data from both sources and to put it in a common format in order to correlate it. This is no mean feat, as there is usually no common time basis between the CAN data and the values provided by the power analyzer, and matching electrical parameters to other sensor data is very challenging. In any case, there is a lot of manual intervention involved, and the procedure is cumbersome, lengthy and error-prone.

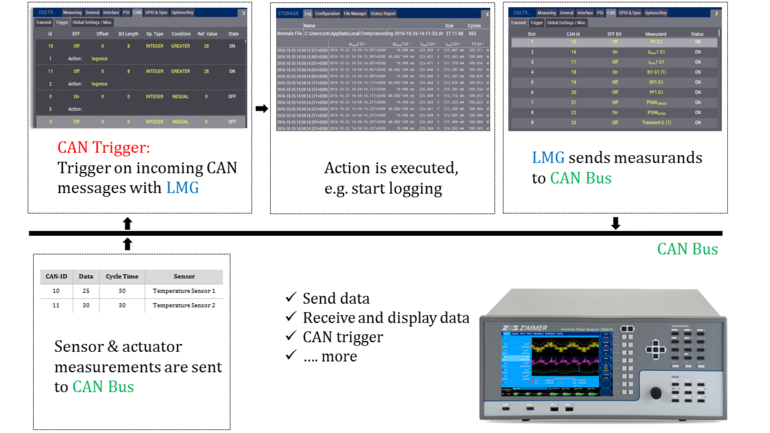

As the only dedicated power analyzer in the world, the LMG600 is able to share up to 128 of its measured variables over CAN bus. This unique capability helps to bridge the gap between the automotive industry’s most popular field bus and traditional test & measurement equipment. Test engineers can now read voltage, current, power etc. the same way they read speed, torque, temperature and other variables: by gathering data from sources on the CAN bus. No separate treatment, no extra work, no distinct data repositories. The necessary time to integrate power measurements into the overall test environment shrinks drastically. The need for additional middleware is eliminated, costs are contained at the necessary minimum.

With the latest firmware release, the LMG600 can also read information sent over the CAN bus and carry out a number of predefined actions based on its content. That is, the CAN bus interface of the power analyzer has become bi-directional, changing it from a purely passive sensor to a remote-controllable analysis tool. This feature offers a convenient way to e.g. trigger data logging based on environmental conditions or change measuring ranges according to the state of the unit under test.

Imagine you would like to initiate logging data once a critical temperature threshold is exceeded at certain location. To implement this procedure you simply would have the LMG600 read the information sent by the respective temperature sensor over CAN and set a trigger condition accordingly. Once the temperature has risen above the limit, recording starts automatically. Likewise, switching an electrical engine off via CAN could simultaneously trigger a range change in the power analyzer, avoiding the otherwise necessary settling period of the auto-ranging mechanism. The LMG600 allows to define up to 128 trigger conditions to cover automation of even the most sophisticated measurement and recording tasks.